Sources: www.weforum.org, energy-transitions.org

Want to read more like this story?

The future of steel production and steel structure construction

Nov, 30, 2022 | NewsThis article will explore four technologies that are helping shape the future of steel construction...

Second Life for Steel: The Rise of Circular Bridges

Apr, 27, 2025 | NewsA shift is underway in civil engineering as reuse—not just recycling—of steel becomes a cornerstone...

UK Steel Industry Under Pressure: Rising Imports and Global Oversupply Threaten Stability

Oct, 15, 2024 | NewsThe UK steel industry is at a critical turning point as global overproduction and an influx of chea...

Researchers produce high strength steel with increased fracture resistance and ductility

May, 07, 2020 | NewsScientists from the University of Hong Kong and the Lawrence Berkeley National Laboratory have manag...

Steel-Framed Curtain Walls: Engineering Marvel at Oklahoma’s Eco-Friendly Bank

Jun, 27, 2024 | NewsThe First United Bank has recently opened a new, state-of-the-art building in Moore, Oklahoma, desi...

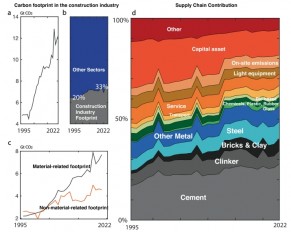

Construction’s carbon footprint to double by 2050, study warns

Nov, 05, 2025 | NewsA new global analysis published in Communications Earth & Environment warns that the constructi...

Unbreakable Glass Strong Like Steel

Nov, 09, 2015 | NewsJapanese scientists claim that they created a glass which is as strong as steel. Japanese scientist...

Composite Metal Foams ready for industry applications

Apr, 01, 2020 | NewsComposite Metal Foams (CFMs) have come closer to commercial applications after successfully passing...

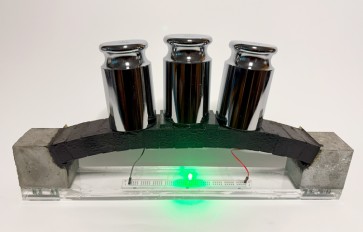

Ductility in Steel Beams Improved by Geometric Cutouts

Mar, 23, 2015 | NewsThe ability of steel buildings to bend without fracturing, or ductility, allows for extreme lateral...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

Morocco Implements Landmark Dam Perforation to Combat Water Stress in Marrakech

The Line at Neom faces feasibility reassessment while construction continues

Dutch greenhouses have revolutionized modern farming

Suspension bridge buckles under force of deadly super typhoon in Philippines

Egypt and Qatar launch $29.7 billion Mediterranean coastal real-estate project