Scientists convert waste plastics into high-value carbon materials

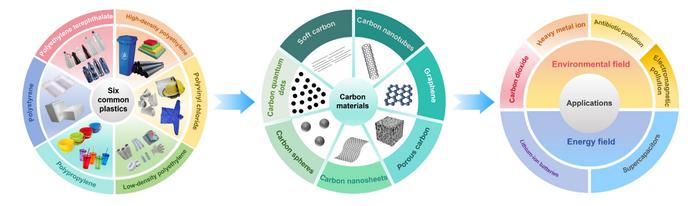

Researchers from Shenyang Agricultural University, the Guangzhou Institute of Energy Conversion (Chinese Academy of Sciences), and South China University of Technology have demonstrated that waste plastics can be transformed into high-value carbon materials such as graphene, carbon nanotubes, porous carbon, and carbon quantum dots, offering a potential pathway to reduce global plastic pollution while supplying materials for energy and environmental technologies.

Published in Sustainable Carbon Materials, the study titled Functional carbon materials from waste plastics: synthesis and applications reviews both established and emerging carbon-conversion technologies capable of recovering carbon from discarded polymers. Each year, over 390 million tons of plastics are produced globally, with a substantial portion disposed of through landfilling, incineration, or poorly managed recycling, all of which contribute to secondary pollution.

Lead author Dr. Gaixiu Yang explains that advanced carbonization approaches can convert plastics into usable carbon frameworks, effectively turning waste into resource. Among these, catalytic pyrolysis, one-pot synthesis, and flash Joule heating are highlighted for their efficiency. In particular, flash Joule heating can transform plastics into high-quality graphene in milliseconds while consuming less than 0.1 kWh per kilogram, significantly lower than conventional manufacturing energy demands.

The resulting carbon products exhibit functional and structural properties suitable for environmental remediation and clean-energy systems. According to the report, porous carbons derived from plastic waste can adsorb CO₂, remove heavy metals and antibiotics from water, and serve as electrodes for lithium-ion batteries and supercapacitors. In one demonstration, plastic-derived porous carbon achieved near-theoretical energy-storage capacities in selenium-based batteries while maintaining high cycling stability.

Despite these advances, the researchers identify several ongoing challenges. These include improving catalyst selectivity, enhancing control over microstructure and yield, and developing scalable industrial processes. Addressing these issues requires interdisciplinary integration across materials science, catalysis, and environmental engineering to achieve both high performance and environmental compliance.

Co-author Professor Yan Chen emphasized that this line of research supports the development of a circular carbon economy, in which discarded plastics serve as feedstock for next-generation materials and energy technologies. By closing the loop between waste generation and renewable-resource production, such innovations could significantly reduce the carbon and waste footprints of industrial systems.

The study provides an optimistic outlook for global sustainability: technologies capable of converting pollution into high-value functional materials could realign industrial waste management with clean-energy goals.

Sources: Sustainable Carbon Materials, EurekAlert

Want to read more like this story?

The prospects for carbon-neutral buildings

Oct, 27, 2023 | NewsIn the United Kingdom, buildings account for 33% of greenhouse gas emissions and 40% of global ener...

By 2050, there could be more plastics than fish in the oceans!

Mar, 04, 2016 | NewsIn a business-as-usual scenario, the ocean is expected to contain 1 ton of plastic for every 3 tons...

Paving the Future: Sustainable Concrete from Plastic Waste

Jan, 22, 2025 | NewsIn a remarkable innovation, engineers have developed sustainable concrete pavers made from nearly 1...

A light aircraft flew more than 500 miles using fuel partially originated from plastic waste

Mar, 08, 2017 | NewsThe initiative ‘On Wings of Waste’ aims to raise awareness about plastic waste recycling...

The First Industrial-Scale Plant For Capturing Carbon Dioxide

Oct, 27, 2015 | NewsClimeworks AG develops the first plant for Carbon Capture carbon dioxide directly. Climeworks AG...

The plastic pollution problem in charts

Dec, 11, 2017 | NewsThe total volume of all plastic ever produced has been calculated at 8.3 bn tonnes (the equival...

New study shows that plastic waste can replace sand in concrete

Sep, 21, 2018 | NewsAccording to researchers from Bath University, waste plastic can replace some of the sand used in co...

Building houses out of plastic waste

Sep, 19, 2016 | NewsA portable machine turns used plastic into bricks A portable machine turns used plastic into bric...

Concrete's Carbon Capture and Structural Longevity with Supercomputing

Oct, 08, 2025 | NewsResearchers at the University of Southern California have achieved a major milestone in material sc...

Trending

Vertical gardens in Mexico City to combat pollution

Characteristics of Load Bearing Masonry Construction

Taipei 101’s impressive tuned mass damper

Dutch greenhouses have revolutionized modern farming

Saudi Park Closed After 360 Big Pendulum Ride Crashes to Ground, 23 injured

The Line at Neom faces feasibility reassessment while construction continues

King Salman Gate unveiled adjacent to Mecca’s Grand Mosque