New study shows that plastic waste can replace sand in concrete

According to researchers from Bath University, waste plastic can replace some of the sand used in concrete.

This change could lead to an environmental friendly solution in construction industry. Concrete is the most consumed material after fresh water as more than 20 billion tons are produced each year worldwide. The mixture of concrete consists of 30% of sand. By replacing about 10% of it with plastic material, over 800 million tons of sand could be saved annually.

In general, plastic materials weaken concrete as they don't bond to the cement mix in the same manner that sand does. Dr. Richard Ball, from Bath’s Department of Architecture & Civil Engineering points out that there needs to be a certain balance between the utilization of plastic and the concrete's strength reduction: “The key challenge here was to have a limit between a small reduction in strengths, which we achieved, and using an appropriate amount of plastic to make it worthwhile. It is really a viable material for use in some areas of construction that might help us to tackle issues of not being able to recycle the plastic and meeting a demand for sand.”

Researchers investigated the impact of 5 finely graded plastics on the structural strength of concrete. A compressive strength of 54 MPa, similar to structural concrete, was achieved by sand-sized PET (Polyethylene Terephthalate) particles deriving from recycled plastic bottles. Dr. Ball stated: “Properties such as the type of plastic and the particle size and shape will all have an influence on the strength of the concrete to which it is added. If we can identify the most favorable properties of the ‘plastic sand’ we may be able to increase the additions allowable without compromising the properties. There are also important factors such as the rheology of the wet mix, environmental durability and fire performance which can be further explored.”

Mr. Orr also said that the team is now investigating the utilization of sources from plastic material that is already graded to the required level.

The study received the Atlas Award for its potential contribution to society.

Source: Theengineer.co.uk

Source: Theengineer.co.uk

Want to read more like this story?

Paving the Future: Sustainable Concrete from Plastic Waste

Jan, 22, 2025 | NewsIn a remarkable innovation, engineers have developed sustainable concrete pavers made from nearly 1...

The plastic pollution problem in charts

Dec, 11, 2017 | NewsThe total volume of all plastic ever produced has been calculated at 8.3 bn tonnes (the equival...

By 2050, there could be more plastics than fish in the oceans!

Mar, 04, 2016 | NewsIn a business-as-usual scenario, the ocean is expected to contain 1 ton of plastic for every 3 tons...

Discarded plastic bottles could be used to make stronger concrete

Jan, 15, 2018 | NewsMIT students have found a way to produce plastic-reinforced concrete that is up to 15% stronger than...

Want to start your own business? Try a plastic recycling workshop!

Apr, 18, 2016 | NewsA 28-year old Dutch has developed machines to recycle plastic, and their blueprints are free on line...

Giant sculptures made entirely out of plastic found on our beaches

Apr, 13, 2016 | NewsTime to reconsider the use and end-of-life management of plastic Time to reconsider the use and e...

Building houses out of plastic waste

Sep, 19, 2016 | NewsA portable machine turns used plastic into bricks A portable machine turns used plastic into bric...

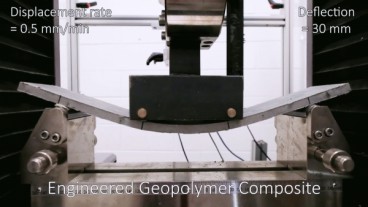

Scientists produce high bending capacity concrete using no cement

Mar, 11, 2020 | NewsScientists from Swinburne University in Melbourne, Australia, have created a new concrete material t...

Indonesia pledges $1 billion annually to tackle ocean pollution

Mar, 22, 2017 | NewsThe country is the second largest plastic polluter in the world after China The country is the se...

Trending

Taipei 101’s impressive tuned mass damper

The Line at Neom faces feasibility reassessment while construction continues

Morocco Implements Landmark Dam Perforation to Combat Water Stress in Marrakech

Characteristics of Load Bearing Masonry Construction

Dutch greenhouses have revolutionized modern farming

Aging bridge breaks in two in Madhya Pradesh, injuring four

Huawei advances unified mining networks across South America