A light aircraft flew more than 500 miles using fuel partially originated from plastic waste

The initiative ‘On Wings of Waste’ aims to raise awareness about plastic waste recycling and draw attention to its potential use as fuel

The initiative ‘On Wings of Waste’ aims to raise awareness about plastic waste recycling and draw attention to its potential use as fuel

In mid-January, a significant takeoff took place at the Illawarra Regional Airport at Wollongong, 90km south of Sydney, Australia. Pilot Jeremy Rowsell set course for Tyabb, a city close to Melbourne, with his light aircraft being filled with conventional fuel blended with 10% fuel manufactured from plastic waste by the UK-based company Plastic Energy. The 500-mile journey was realized under the ‘On Wings of Waste’ campaign, which aims to raise awareness about plastic waste recycling and draw attention to its potential use as fuel. Under the banner of the ‘10 per cent solution’, the venture proved that fuel coming from plastic waste can perform just fine when blended with JetA1 fuel.

The project started after Rowsell witnessed first-hand from the air the severe sea and land pollution. Thinking about the environment and the consequences of the aviation industry using toxic and damaging fuels, he came up with the idea of creating a greener fuel that could be used in aviation. ‘After years of preparation and many ups and downs we´ve finally shown that the eight million tonnes of plastic dumped into the oceans each year can be put to good use’, said Jeremy. ‘We blended 10% of fuel manufactured by Plastic Energy with conventional fuel and the flight was a dream.’

The campaign has 4 objective targets: Recycle – persuading people to recycle, Reuse – plastic waste transformed into fuel and be blended with JetA1, Refuel – airlines to start using a 10% blend of fuel derived from plastic waste and Rescue - pollution of the world’s oceans to be slowed down and eventually halted.

The converting technology

For the manufacture of fuel derived from plastic waste, a process called TAC (Thermal Anaerobic Conversion) is used. Plastics are heated in an oxygen-free environment to prevent them from burning, so there are no toxic emissions released in the environment. Because of the melting process, the waste plastic is broken into component hydrocarbons to create the equivalent of a petroleum distillate, which can then be separated into different fuels. The end product is a high quality, low sulphur diesel.

The environmental benefit

An A747 aircraft burns approximately 36,000 UK gallons of fuel on a 10,000 mile journey and 33% of airlines’ operating costs are spent on fuel. For the ‘10% concept’, 18 tonnes of waste would be needed in order to produce the 3,600 UK gallons for the fuel blend. Considering the 1,200 flights a day made from Heathrow airport, 21,600 tonnes of waste plastic could be transformed to fuel every day instead of ending up in the oceans.

Plastic Energy uses end of life plastic, normally found in garbage patches in the ocean and landfill sites. 95% of the end of life material is usable for diesel fuel and the remaining 5% known as 'Char' is a solid used, for example, for fuel additives and pigments. "Jeremy´s flight is a tremendous opportunity to showcase how plastic waste can be put to productive use instead of thrown away to pollute the oceans or despoil the land. We are delighted to be supporting this adventure", said Carlos Monreal, Plastic Energy’s President and CEO.

The two-seat Vans RV-9.

On Wings of Waste pilot Jeremy Rowsell.

Want to read more like this story?

The plastic pollution problem in charts

Dec, 11, 2017 | NewsThe total volume of all plastic ever produced has been calculated at 8.3 bn tonnes (the equival...

By 2050, there could be more plastics than fish in the oceans!

Mar, 04, 2016 | NewsIn a business-as-usual scenario, the ocean is expected to contain 1 ton of plastic for every 3 tons...

Indonesia pledges $1 billion annually to tackle ocean pollution

Mar, 22, 2017 | NewsThe country is the second largest plastic polluter in the world after China The country is the se...

This machine produces oil from plastic waste

Mar, 31, 2017 | NewsA household appliance that converts plastic bags into fuel was invented by a Japanese man A house...

Building houses out of plastic waste

Sep, 19, 2016 | NewsA portable machine turns used plastic into bricks A portable machine turns used plastic into bric...

Giant sculptures made entirely out of plastic found on our beaches

Apr, 13, 2016 | NewsTime to reconsider the use and end-of-life management of plastic Time to reconsider the use and e...

Want to start your own business? Try a plastic recycling workshop!

Apr, 18, 2016 | NewsA 28-year old Dutch has developed machines to recycle plastic, and their blueprints are free on line...

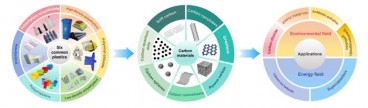

Scientists convert waste plastics into high-value carbon materials

Nov, 01, 2025 | NewsResearchers from Shenyang Agricultural University, the Guangzhou Institute of Energy Conversion (Ch...

Airline food waste: 5.2 million tons were thrown away in 2016 alone

Apr, 19, 2017 | NewsCabin waste costs the industry $500m per year, according to IATA Cabin waste costs the industry $...

Trending

Taipei 101’s impressive tuned mass damper

The Line at Neom faces feasibility reassessment while construction continues

Morocco Implements Landmark Dam Perforation to Combat Water Stress in Marrakech

Characteristics of Load Bearing Masonry Construction

Dutch greenhouses have revolutionized modern farming

Aging bridge breaks in two in Madhya Pradesh, injuring four

Huawei advances unified mining networks across South America