New sustainable material that will replace steel in reinforced concrete

A new technique that involves replacing steel with polyethylene in reinforced concrete has been developed.

The new material was created in the Structural Maintenance and Safety Laboratory (MCS) of the École Polytechnique Fédérale de Lausanne (EPFL) from Amir Hajiesmaeili, a Ph.D. researcher. MCS laboratory is currently focusing on two purposes: 1) Introducing a concrete mixture that will be more environmental-friendly and 2) Assessing the performance of existing infrastructure in Switzerland and all over the world.

Reducing building materials' environmental footprint is crucial as the construction industry is responsible for about 40% of the total carbon emissions worldwide. Therefore, the technology and materials used in infrastructure should develop to become environmentally sustainable.

The material that is the next generation of UHPFRC (Ultra High-Performance Fiber-Reinforced Concrete), will have the same strength and durability of steel concrete but will result in about 60-70% fewer carbon emissions.

Hajiesmaeili tried various types of mixtures and conducted laboratory tests to derive the compressive and tensile strength of the produced materials for 3 years before discovering the perfect combination. Finally, he managed to develop a mixture using polyethylene to replace steel fiber and limestone to replace half of the cement's quantity, with the same characteristics as reinforced steel concrete and also 10% lighter. “After three years of this trial-and-error, we finally found the right recipe – one that also meets stringent building standards. The trick was to find a material that’s very strong and produces the right consistency,” Hajiesmaeili, stated.

During the last 15 years, similar materials, known as the first generation of UHPFRC, have been developed in the MCS laboratory and have been used in the reinforcement of more than 100 structures in Switzerland. According to Eugen Brühwiler, Professor of Structural Engineering at the EPFL and head of MCS, repairing existing infrastructure is more efficient than rebuilding them. “This solution is also much more financially and environmentally sound than razing and rebuilding existing structures like bridges and historical monuments," Prof. Brühwiler, stated.

The new material is going to be used for the first time to reinforce a bridge in 2020.

Sources: EPFL Theengineer.co.uk

Sources: EPFL, Theengineer.co.uk

Want to read more like this story?

3D-printed buildings using soil material

Sep, 24, 2020 | NewsResearchers have developed a new technique to construct a building using a 3-D printer and soil mate...

The world’s first carbon concrete building constructed by researchers in Germany

Nov, 17, 2022 | NewsThe first building made of carbon-reinforced concrete was inaugurated in September after two and a...

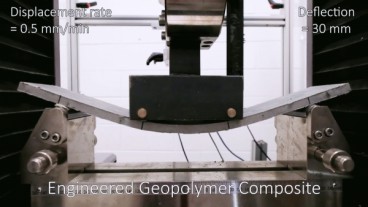

Scientists produce high bending capacity concrete using no cement

Mar, 11, 2020 | NewsScientists from Swinburne University in Melbourne, Australia, have created a new concrete material t...

Researchers produce high strength steel with increased fracture resistance and ductility

May, 07, 2020 | NewsScientists from the University of Hong Kong and the Lawrence Berkeley National Laboratory have manag...

What about recycled concrete?

Feb, 01, 2016 | NewsA group of scientists examines the possibility of using materials from demolitions for the construct...

New research on more efficient bridges

Jun, 01, 2020 | NewsA new study reveals the high potential of reducing the materials used in suspension bridge construct...

MIT engineers create energy-storing cement mixture

Jul, 31, 2023 | NewsA paper was published on the last day of July, by a team of MIT researchers, regarding the creation...

Astronauts investigate what happens to concrete when it's mixed in space

Sep, 11, 2019 | NewsIn an innovative attempt, astronauts examined what happens to concrete when it's produced in sp...

Concrete's Carbon Capture and Structural Longevity with Supercomputing

Oct, 08, 2025 | NewsResearchers at the University of Southern California have achieved a major milestone in material sc...

Trending

Vertical gardens in Mexico City to combat pollution

Saudi Park Closed After 360 Big Pendulum Ride Crashes to Ground, 23 injured

Characteristics of Load Bearing Masonry Construction

Taipei 101’s impressive tuned mass damper

Dutch greenhouses have revolutionized modern farming

Federal court rules Biden’s offshore drilling ban unlawful