Scientists produce high bending capacity concrete using no cement

Scientists from Swinburne University in Melbourne, Australia, have created a new concrete material that needs no cement to be produced and performs better when subjected to high bending moments.

Concrete is the most widely used building material and the second most utilized substance after water worldwide. It is made out of cement, water and aggregates. The production of cement is an environmentally harmful process that is responsible for 8% of the world's total carbon dioxide emissions. Thus, reducing the concrete's environmental footprint requires a radical approach regarding cement's utilization.

Scientists have introduced a new type of concrete made of waste materials (e.g. fly ash) with zero cement usage. Those materials are capable of hardening at room temperature and, thus, they are more eco-friendly. A similar approach to produce concrete from waste materials has been attempted before, but, the scientific team has also achieved another impressive feature. The produced material has high bending capacity and presents greater ductility than conventional concrete.

It is also not the first time that scientists attempt to produce the so-called "bendable concrete". In fact, it is a technology developed in the 1990s at the University of Michigan, but it hasn't been widely used due to cost issues and supply chain problems. Of course, that kind of bendable concrete uses cement in the mixture and has been a far more polluting process. “Production of this novel concrete requires about 36 percent less energy and emits up to 76 percent less carbon dioxide as compared to conventional bendable concrete made of cement,” Dr. Behzad Nematollahii, lead author of the study and ARC DECRA Fellow at Swinburne's Centre for Smart Infrastructure and Digital Construction, stated.

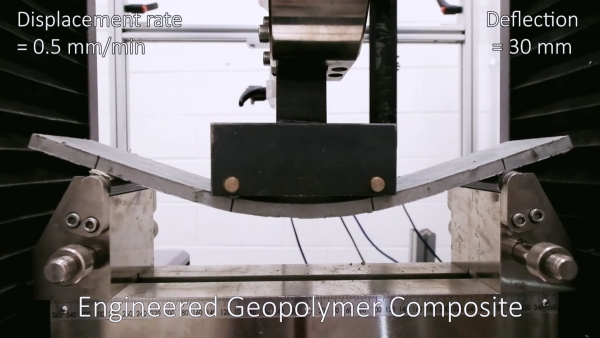

Bendable behavior was achieved by adding polymeric fibers in the mixture that make the material less brittle. Even if cracks propagate, the material will bear a load without shattering, a performance that is beneficial in dynamic loads induced by earthquakes or blasting. According to the researchers, the new material has similar compressive strength to the conventional concrete but it is 400 times more bendable.

Consequently, scientists have managed to combine 2 technologies and achieved an environmental-friendly concrete that also performs better when subjected to high bending moments. The team has not clarified when the new material will be available for commercial use in the construction industry.

Click the video below to watch bending tests conducted in 2 specimens, one made of conventional concrete and the other made of the new material.

Source: Swinburne University, NewAtlas

Sources: Swinburne University, NewAtlas

Media

- Bendable cement-free concrete

- Swinburne University

Want to read more like this story?

3D-printed buildings using soil material

Sep, 24, 2020 | NewsResearchers have developed a new technique to construct a building using a 3-D printer and soil mate...

What about recycled concrete?

Feb, 01, 2016 | NewsA group of scientists examines the possibility of using materials from demolitions for the construct...

Astronauts investigate what happens to concrete when it's mixed in space

Sep, 11, 2019 | NewsIn an innovative attempt, astronauts examined what happens to concrete when it's produced in sp...

Recycled aggregate concrete as an alternative to conventional concrete

Nov, 30, 2020 | NewsA new research focuses on the potential of concrete made of recycled aggregates and compares its per...

The world’s first carbon concrete building constructed by researchers in Germany

Nov, 17, 2022 | NewsThe first building made of carbon-reinforced concrete was inaugurated in September after two and a...

New sustainable material that will replace steel in reinforced concrete

Dec, 27, 2019 | NewsA new technique that involves replacing steel with polyethylene in reinforced concrete has been deve...

Rare mineral that improves the long-term performance of concrete

Feb, 05, 2021 | NewsScientists from Nagoya University have detected a rare mineral that improves the mechanical pro...

Concrete's Carbon Capture and Structural Longevity with Supercomputing

Oct, 08, 2025 | NewsResearchers at the University of Southern California have achieved a major milestone in material sc...

MIT engineers create energy-storing cement mixture

Jul, 31, 2023 | NewsA paper was published on the last day of July, by a team of MIT researchers, regarding the creation...

Trending

Vertical gardens in Mexico City to combat pollution

Saudi Park Closed After 360 Big Pendulum Ride Crashes to Ground, 23 injured

Characteristics of Load Bearing Masonry Construction

Taipei 101’s impressive tuned mass damper

Dutch greenhouses have revolutionized modern farming

Federal court rules Biden’s offshore drilling ban unlawful