Researchers produce high strength steel with increased fracture resistance and ductility

Scientists from the University of Hong Kong and the Lawrence Berkeley National Laboratory have managed to create a steel product that presents high strength, cracking resistance and ductility.

In a study, recently published in Science Magazine, researchers present a technique to produce Dual-phase steel that can be used in the industry. The produced material has increased ductility and fracture resistance while preserving the steel's high strength.

Steel is a material widely used in civil engineering. It can be utilized alone to form steel structures or alongside with concrete to form most of the modern buildings (reinforced concrete). Concrete behaves great in compression but lacks significant tensile strength. Therefore, it is reinforced with steel to bear the tensile stresses. Steel also provides durability and sustainability while it is a cost-efficient material.

Nevertheless, in industry, engineers constantly aim at developing new materials that could satisfy 3 major criteria:

1. Strength

2. Ductility

3. Fracture resistance (toughness)

The efforts to accomplish such a task have not always been successful due to a major reason. In most of the techniques used, when one of those attributes is enhanced, the others will be undermined. Therefore, an increase in ductility will result in a deterioration in strength and the opposite. The phenomenon is known as strength-ductility trade-off dilemma.

Dual-phase steel is a type of steel that acquires a ferritic–martensitic microstructure. When it is stressed, the strain is concentrated in the ferrite parts which are generally soft and present ductility. The islands of martensite have increased tensile strength ultimately providing the material with higher load capacity. However, dual-phase steel has not fully tackled the strength-ductility trade-off and new efforts to produce better combinations are underway.

Scientists created the new steel material through a unique deformed and partitioned method. According to the authors, their technique resulting in a material with great performance considering all factors examined (strength, ductility and toughness).

“In this latest breakthrough in super D&P steel, we attained an unprecedented strength-toughness combination which can address a major challenge in safety-critical industrial applications – to attain an ultra-high fracture toughness so as to prevent catastrophic premature fracture of structural materials. The breakthrough also changes the conventional view that attaining high strength will be at the expense of deteriorating toughness, which invariably leads to the embrittlement of structural materials and greatly limits their application,” Huang Mingxin, co-author of the study and a Professor at the Department of Mechanical Engineering of the University of Hong Kong, stated.

The behavior of the material is associated with the propagation of multiple micro-cracks which are formed below a main fracture, absorbing energy and providing a "toughening mechanism".

Laboratory tests conducted in Lawrence Berkeley National Lab on the new steel, yielded a tensile strength of 2000 MPa, deformability of 19% and an intensity factor of 102 MPa*m1/2. In comparison, typical steel has a tensile strength of 350 MPa, deformability of 15% and intensity factor of 50 MPa*m1/2.

Source: University of Hong Kong

Source: University of Hong Kong

Want to read more like this story?

The future of steel production and steel structure construction

Nov, 30, 2022 | NewsThis article will explore four technologies that are helping shape the future of steel construction...

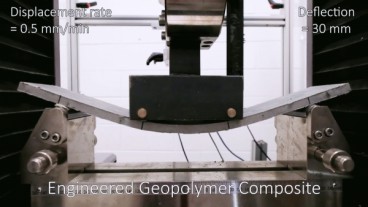

New sustainable material that will replace steel in reinforced concrete

Dec, 27, 2019 | NewsA new technique that involves replacing steel with polyethylene in reinforced concrete has been deve...

Green Steel Production: The Future of Civil Engineering

Jun, 21, 2024 | NewsThe Importance of Steel in Modern Construction Steel is the backbone of contemporary construction,...

Second Life for Steel: The Rise of Circular Bridges

Apr, 27, 2025 | NewsA shift is underway in civil engineering as reuse—not just recycling—of steel becomes a cornerstone...

Ductility in Steel Beams Improved by Geometric Cutouts

Mar, 23, 2015 | NewsThe ability of steel buildings to bend without fracturing, or ductility, allows for extreme lateral...

Composite Metal Foams ready for industry applications

Apr, 01, 2020 | NewsComposite Metal Foams (CFMs) have come closer to commercial applications after successfully passing...

UK Steel Industry Under Pressure: Rising Imports and Global Oversupply Threaten Stability

Oct, 15, 2024 | NewsThe UK steel industry is at a critical turning point as global overproduction and an influx of chea...

Scientists produce high bending capacity concrete using no cement

Mar, 11, 2020 | NewsScientists from Swinburne University in Melbourne, Australia, have created a new concrete material t...

3D-printed buildings using soil material

Sep, 24, 2020 | NewsResearchers have developed a new technique to construct a building using a 3-D printer and soil mate...

Trending

Vertical gardens in Mexico City to combat pollution

Saudi Park Closed After 360 Big Pendulum Ride Crashes to Ground, 23 injured

Characteristics of Load Bearing Masonry Construction

Taipei 101’s impressive tuned mass damper

Dutch greenhouses have revolutionized modern farming

Federal court rules Biden’s offshore drilling ban unlawful