Huawei advances unified mining networks across South America

Huawei is expanding mining connectivity solutions in South America with an emphasis on unified networks that support automation and artificial intelligence. At Exposibram 2025 in Salvador, Brazil, Theodore Shao, Vice President of Mining, Oil and Gas in LATAM for Huawei, outlined connectivity challenges in Brazil and the region, citing hilly and forested terrain, inconsistent cellular coverage, and permitting constraints for permanent towers, including environmental and aviation regulations.

To address these conditions, Huawei is deploying Cell on Wheels (COW) units—portable base stations with telescopic masts, antennas and onboard power—that can be rapidly positioned on access roads or small clearings to avoid deforestation. The stations create 5G “bubbles” that can be merged to form continuous coverage and can extend networks to remote satellite pits without fixed infrastructure capital expenditure. This approach has been implemented at Vale’s Carajás operation in the Gelado project, which produces pellet feed by reusing tailings deposited since 1985. Vale is using the network for remote control of amphibious excavators and plans future remote control of 100% electric dredgers, selecting COW for agility and flexibility in tailings dam operations. The project is described as the first end-to-end remote mining control solution using a private 5G network in Latin America. It reuses existing infrastructure, employs solar power and energy storage where grid power is deficient, and uses five COW stations around the Gelado dam area. A dual-band 4G/5G network supports services and reliability: 4G provides MCPTT voice and emergency communications, while 5G carries uplink video and data for remote control. Data remains within the mining area, the MAE-Light Network Management System meets local operation and maintenance requirements, and Vale holds the O&M permissions for the private 5G network.

Huawei is engaging with mining companies in Brazil and Chile to apply the same portable coverage model. While permanent tower restrictions differ in Chile’s Atacama, COW units offer rapid deployment in remote locations. Some South American mines are also considering maintaining LTE 4G for wide-area coverage and deploying 5G in specific low-latency zones, such as autonomous haulage or teleoperation areas; Huawei’s converged core enables this using the same antennas and base stations.

Beyond private 5G, Huawei is proposing comprehensive connectivity architectures for surface and underground operations, including active campus networks and passive GPON solutions using OptiXstar ONTs and OLTs. In Peru, Huawei deployed the first FTTM + WiFi6 solution for underground mines in South America, comprising GPON sets, WiFi6 sets, eSight and iMaster NCE Campus, with plug-and-play commissioning. The underground optical design includes Optical Ring Passive and Optical Ring End links, with surface Optical Distribution Networks delivering signals to ONUs for connected devices. Huawei has operated in Peru for decades and currently has seven open-pit LTE 4G networks at mines including Toquepala, Toromocho, Cuajone and Constancia, in cooperation with Telefónica Peru and Claro Peru; two of these LTE 4G networks have been upgraded to 5G. Huawei states that these deployments aim to ensure continuous connectivity and to future-proof mines for potential autonomous haulage systems that do not rely on predetermined path tracking.

In Chile, Huawei signed a memorandum of understanding with Codelco in July 2025 to explore on-site connectivity, energisation and the use of artificial intelligence for automation and efficiency. The scope includes connectivity in open-pit and underground operations, cloud services and technologies applied to mining processes, with work underway on personnel tracking and monitoring to enhance safety at large mines such as El Teniente. Huawei also completed a private LTE 4G network installation at Codelco Andina in 2024.

Huawei’s autonomous driving system places intelligence on the haul truck, enabling obstacle identification, local path adjustment and cloud updates for following vehicles. The system is in use in China at mines including Yimin, JISCO, Xigou, Jinding and Yulong. It integrates LiDAR, 4D mmWave radar and cameras feeding an on‑truck MDC (Mobile Data Center), which controls the vehicle via a 5G T‑box and connects to 5G/RTK base stations and the cloud through an onboard RTK terminal. Teleoperation solutions for shovels and drills—already applied in China—use AI‑enhanced multimodal sensing to deliver a wide viewing angle, 4K at 60 fps video and latency of under 180 ms. Algorithms address vibration, low lighting, dust, fog and image distortion, with force feedback for operator perception, one‑click loading and centimetre‑level positioning and track planning accuracy exceeding 95%.

Huawei’s F5G (Fifth Generation Fixed Network) offering aggregates WiFi6/WiFi7, LAN switches, firewalls, SD‑WAN, 4G/5G, optical DWDM, optical access, routers, DCN for SCADA and DCS, storage, virtual OS, cloud and meeting platforms into a unified optical network for “life of mine” coverage, from exploration through closure. The approach aims to minimize the need for multiple providers, simplify management, enhance security and reduce investment cost, while supporting AI and autonomy via network slicing. For mineral processing plants, Huawei emphasizes GPON passive networks due to harsh conditions, reduced active components and lower energy use, while active campus networks are applied in mine offices.

Interest is also growing in digital twins for mining and processing, supported by Huawei’s Pangu Mine Model, which is trained using operational data and digitised human expertise, including ore blending practices, grade block models, face XRF scanning, acoustic cues from milling and vibration/condition monitoring. For critical communications in low‑coverage or outage scenarios, Huawei’s MiniRapid Pro provides a portable 5G core and base station with one‑click startup. It can be vehicle‑mounted or carried by a single person, use Starlink as backhaul, and deliver a coverage radius of up to 1 km (extendable to 3 km with an external antenna), with up to four hours of battery operation before requiring external power.

Source: International Mining

Want to read more like this story?

DOE to test cutting-edge mining technologies at four U.S. mines

Sep, 30, 2025 | NewsThe U.S. Department of Energy (DOE) has launched a new funding initiative totaling US $95 million k...

$22 million state funding backs Stony Brook’s two geothermal network projects

Oct, 29, 2025 | NewsThe Stony Brook University (SBU) has secured US $22 million in funding to design and construct two...

Copper mines in arizona targeted for reopening by BHP

Oct, 17, 2025 | NewsBHP, the global mining giant, is evaluating plans to restart operations at at least three copper mi...

Challenges for sustainable road networks in UK

Jan, 10, 2021 | NewsPreserving road networks is a challenging and abiding task that requires both short-term and lo...

Open-pit coal mine collapse in China

Mar, 02, 2023 | NewsAn open-pit coal mine collapsed in Alxa League in Inner Mongolia, China, on Wednesday the 22nd of...

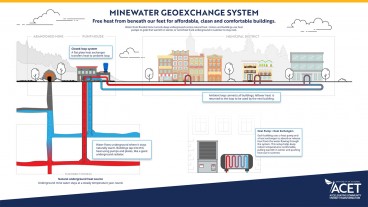

University-led initiative assesses mine-water district energy in Cumberland, B.C.

Nov, 25, 2025 | NewsCumberland, British Columbia, is partnering with the University of Victoria-led Accelerating Commun...

Maybe RES Do Not Need Energy Storage!

Nov, 03, 2015 | NewsRenewable Energy Sources have the largest part in the electrical power that is installed each year a...

AI-Powered Bridge Monitoring: Detecting Structural Failures Before They Happen

Feb, 10, 2025 | NewsBridges are critical components of transportation networks, yet their maintenance often relies on r...

South African tailings dam collapses: Injuries and ‘extensive damage’

Oct, 07, 2022 | NewsEmergency teams are on the ground in South Africa’s Free State province after a dam collapsed at an...

Trending

Taipei 101’s impressive tuned mass damper

The Line at Neom faces feasibility reassessment while construction continues

Morocco Implements Landmark Dam Perforation to Combat Water Stress in Marrakech

Characteristics of Load Bearing Masonry Construction

Dutch greenhouses have revolutionized modern farming

Aging bridge breaks in two in Madhya Pradesh, injuring four

Britain delivers hydrogen by rail for the first time