Cementing Green Change: North Wales to Host First CCS Cement Facility

Sources: newcivilengineer.com, thechemicalengineer.com, bbc.com

Want to read more like this story?

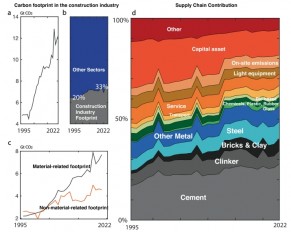

Construction’s carbon footprint to double by 2050, study warns

Nov, 05, 2025 | NewsA new global analysis published in Communications Earth & Environment warns that the constructi...

The First Industrial-Scale Plant For Capturing Carbon Dioxide

Oct, 27, 2015 | NewsClimeworks AG develops the first plant for Carbon Capture carbon dioxide directly. Climeworks AG...

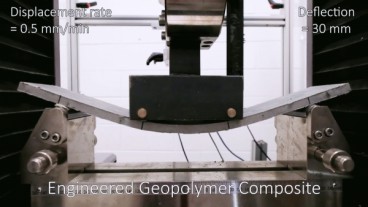

Scientists produce high bending capacity concrete using no cement

Mar, 11, 2020 | NewsScientists from Swinburne University in Melbourne, Australia, have created a new concrete material t...

The prospects for carbon-neutral buildings

Oct, 27, 2023 | NewsIn the United Kingdom, buildings account for 33% of greenhouse gas emissions and 40% of global ener...

From Emissions to Solutions: The Rise of Carbon-Storing Highways

Mar, 30, 2025 | NewsThe UK is at a turning point in road construction. As the government shapes its Road Investment Str...

Green Steel Production: The Future of Civil Engineering

Jun, 21, 2024 | NewsThe Importance of Steel in Modern Construction Steel is the backbone of contemporary construction,...

UK pilots Europe’s first bioenergy carbon capture storage (BECCS) project

Jun, 27, 2018 | NewsIf successful, it could make the renewable electricity produced at biomass power stations carbon neg...

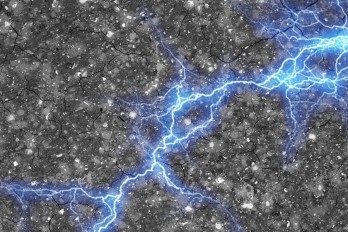

MIT engineers create energy-storing cement mixture

Jul, 31, 2023 | NewsA paper was published on the last day of July, by a team of MIT researchers, regarding the creation...

The Fehmarnbelt Tunnel’s Pushes Forward with Low-Carbon Engineering

Nov, 20, 2024 | NewsThe Fehmarnbelt tunnel project is at the forefront of sustainable engineering with its trial of CO2...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

China Completes World’s Longest Expressway Tunnel, Redefining Connectivity

The Line at Neom faces feasibility reassessment while construction continues

The Billion-Dollar Airport Boom: 2025 Megaprojects Shaping the Skies

World's longest expressway tunnel to link northern and southern Xinjiang