Temporary Works Go Digital: Enhancing Safety and Sustainability

Sources: .jarvisbuild.co.uk, projectscot.com, newcivilengineer.com

Want to read more like this story?

Civil Engineering in the Digital Age: Top Innovations Shaping the Future

Jul, 16, 2024 | NewsThe world of civil engineering is experiencing a significant digital transformation. Innovative tec...

Engineering Considerations for Temporary Support in Existing Structures

Jun, 23, 2025 | NewsConstruction within existing buildings often involves unique structural challenges that demand care...

AI-Enabled Tunnel Installations: Ensuring Safety and Efficiency with DATA-IS

Sep, 19, 2024 | NewsIn an innovative step forward, an engineering team has successfully trialed a cutting-edge digital...

Carbon Reduction in Focus: Lessons from the Edge London Bridge Project

Jan, 20, 2025 | NewsA bold new addition to London’s skyline is taking shape near London Bridge. This 27-storey sustaina...

Pioneering the Future of Construction Health & Safety: Global Trends for 2025

Jan, 10, 2025 | NewsThe construction industry worldwide is undergoing a transformation driven by technological innovati...

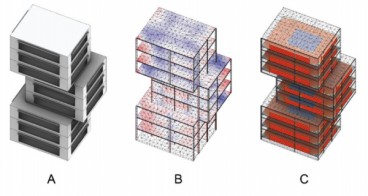

New simulation tool for building design

Jan, 10, 2021 | NewsA new simulation tool that utilizes many variables for the design and the initial phases of the buil...

Revolutionizing Military Engineering with 3D-Printed Concrete Structures

Dec, 09, 2024 | NewsWhen military missions require immediate infrastructure such as bridges or buildings, shipping mate...

Monitoring infrastructure via Digital Twins

Jun, 26, 2020 | NewsInfrastructure monitoring can be completely retrofitted utilizing a concert known as Digital Twins....

The correlation between direct work and productivity in construction industry

Jul, 16, 2020 | NewsA new study focuses on a crucial relationship that impacts the construction industry. The correlatio...

Trending

Vertical gardens in Mexico City to combat pollution

Characteristics of Load Bearing Masonry Construction

Taipei 101’s impressive tuned mass damper

Morocco Implements Landmark Dam Perforation to Combat Water Stress in Marrakech

Dutch greenhouses have revolutionized modern farming

The Line at Neom faces feasibility reassessment while construction continues

A new chapter for Sunderland: The £31 million Keel Crossing opens