PolyU deploys ai-enabled bridge inspection system across 11 Hong Kong bridges

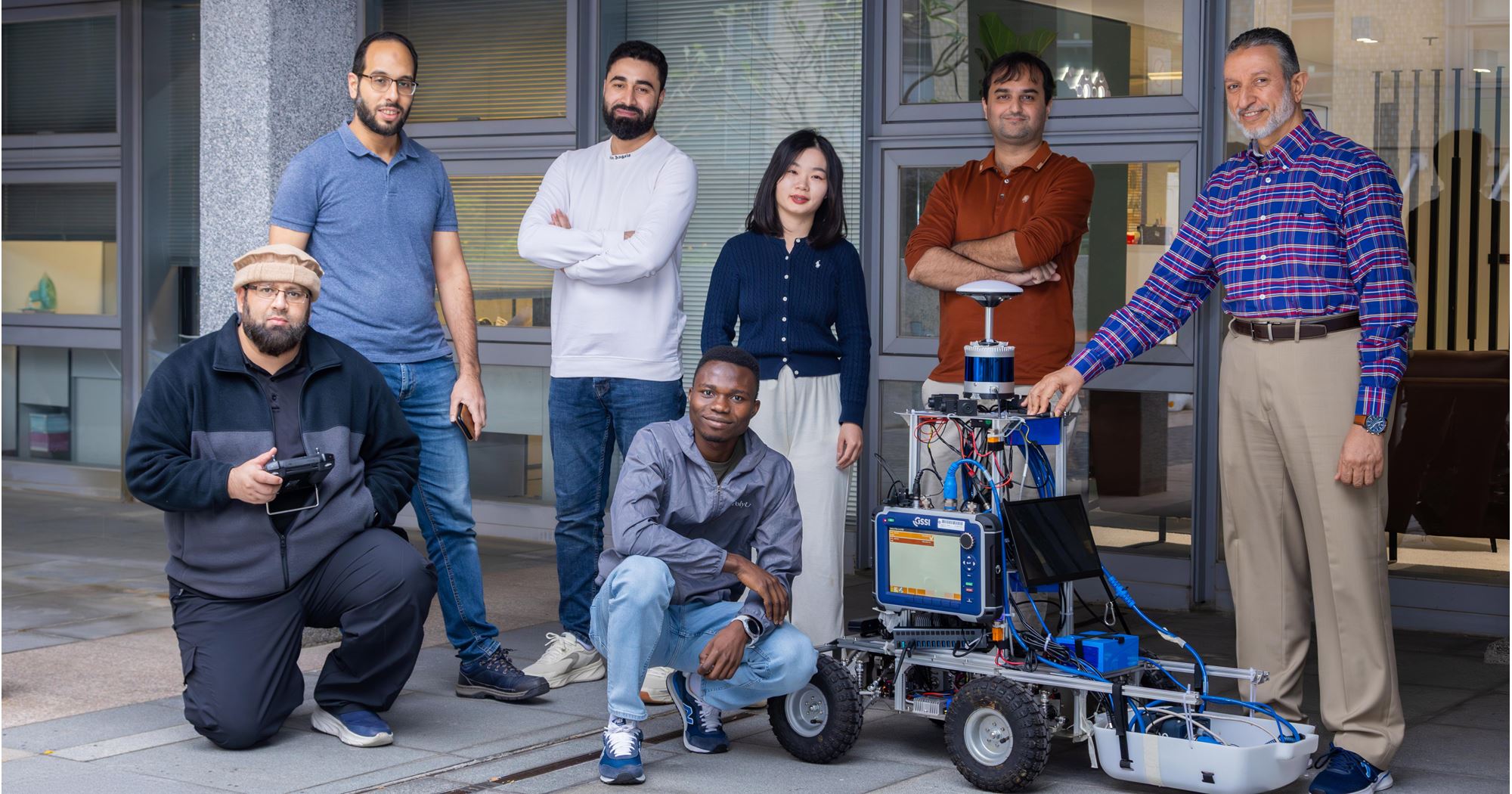

A research team at The Hong Kong Polytechnic University (PolyU) has unveiled an intelligent bridge inspection system that integrates proprietary non-destructive testing (NDT) technologies with advanced artificial intelligence (AI) models. Deployed across 11 bridges in Hong Kong, the multi-tier system detects cracks and uncovers hidden structural flaws invisible to the human eye, cutting inspection time by 50% and increasing overall accuracy to 80%, paving the way for citywide adoption.

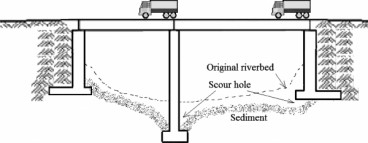

According to PolyU, traditional visual inspection (VI) methods in Hong Kong are labor-intensive, subjective and often miss subsurface defects such as rebar corrosion, which necessitate road closures. Led by Prof. Tarek ZAYED of the PolyU Department of Building and Real Estate, the new approach replaces manual practices with drones, ground-penetrating radar (GPR) and infrared thermography (IRT) to collect surface and subsurface data, while AI models automate analysis.

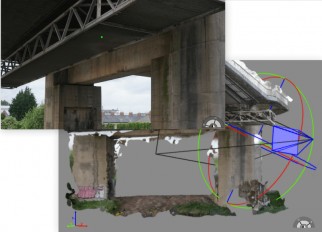

For surface crack identification, the team combined drone-enabled VI with a self-developed deep convolutional neural network model, Smart Bridge Deck Efficiency (SBDE). The model achieved superior crack detection in challenging conditions such as low light or shadows, outperformed other leading object detection models, and reduced false positives and confusion with surface scratches.

Addressing subsurface defects, the team’s fully automated GPR data interpretation model locates rebars with over 98% precision and maps potential corrosion zones using advanced amplitude analysis and clustering, significantly streamlining the GPR-based corrosion assessment process. For concrete deterioration, including spalling and delamination, an optimum thermal gradient threshold (OTGT) system for IRT adjusts thresholds based on environmental conditions, with a smart OTGT-based model that automatically generates delamination maps.

“This hybrid system, for surface and subsurface defects, enhances both the efficiency and accuracy of bridge inspection through an integrated, AI-powered approach,” said Prof. Tarek Zayed. “We have also standardized inspections with a five-point severity scale to facilitate diagnosis and prioritize repairs. The comprehensive SBDE tool thoroughly assesses bridge conditions based on data collected from various sensing devices.” He added, “We are currently exploring further collaboration with relevant government departments and industry partners to implement this system for regular bridge inspections in the City, marking a significant step towards smarter infrastructure management in Hong Kong. Our goal is to ensure that Hong Kong's bridges remain safe and reliable for decades to come.”

The two-year project was supported by the Smart Traffic Fund. Findings have been published in international journals including Construction and Building Materials, Automation in Construction and Advanced Engineering Informatics, and the team is exploring ways to advance related technologies and further promote smart bridge inspection in Hong Kong.

Want to read more like this story?

Link to mega bridge completed in Hong Kong

Apr, 26, 2017 | NewsHong Kong's Highways Department has announced that a 12 km long tunnel and viaduct link to the Hong...

Digital Twin Infrastructure: Building Safer Bridges with AI

Aug, 20, 2025 | NewsArtificial intelligence is emerging as a powerful tool to improve the safety and resilience of brid...

Researchers developed AI-based algorithms for real-time structural assessment of bridges

Sep, 26, 2023 | NewsBridges play a crucial role in India's infrastructure, with approximately 13,500 of them spread acr...

AI-Powered Bridge Monitoring: Detecting Structural Failures Before They Happen

Feb, 10, 2025 | NewsBridges are critical components of transportation networks, yet their maintenance often relies on r...

Four metro tunnels are completed in Hong Kong

Dec, 06, 2021 | NewsDragages Hong Kong has built one of Hong Kong’s most technically challenging series of tunnels – pa...

The world's longest sea bridge will also be ‘green’, featuring electric vehicle charging stations

Sep, 01, 2017 | NewsThe first major combined bridge and tunnel sea-crossing project in China is the Hong Kong-Zhuhai-Mac...

Hong Kong plans to launch a debatable artificial island project

Mar, 26, 2019 | NewsHong Kong plans to launch a controversial $80 billion artificial island project. According to Hon...

Global study shows spaceborne radar can accurately monitor bridge health

Oct, 13, 2025 | NewsA new international study has demonstrated that satellite-based monitoring can transform the way en...

How climate change is affecting the safety of bridges

Oct, 15, 2019 | NewsA new study, recently published in the American Society of Civil Engineers (ASCE) Jou...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

China Completes World’s Longest Expressway Tunnel, Redefining Connectivity

The Line at Neom faces feasibility reassessment while construction continues

The Billion-Dollar Airport Boom: 2025 Megaprojects Shaping the Skies

World's longest expressway tunnel to link northern and southern Xinjiang