New Sustainable Concrete Mix Cuts Emissions and Boosts Strength

Sources: techxplore.com, 3dprintingindustry.com

Want to read more like this story?

3D-printed buildings using soil material

Sep, 24, 2020 | NewsResearchers have developed a new technique to construct a building using a 3-D printer and soil mate...

Revolutionizing the Water Industry: The Impact of 3D Concrete Printing

Jun, 13, 2024 | NewsIn an ambitious leap forward, United Utilities, a major water company in North-West England, has pa...

Civil Engineering in the Digital Age: Top Innovations Shaping the Future

Jul, 16, 2024 | NewsThe world of civil engineering is experiencing a significant digital transformation. Innovative tec...

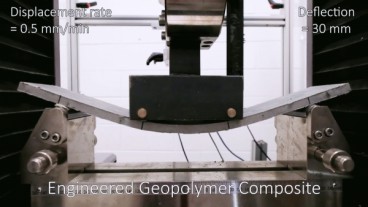

Scientists produce high bending capacity concrete using no cement

Mar, 11, 2020 | NewsScientists from Swinburne University in Melbourne, Australia, have created a new concrete material t...

What about recycled concrete?

Feb, 01, 2016 | NewsA group of scientists examines the possibility of using materials from demolitions for the construct...

The Fehmarnbelt Tunnel’s Pushes Forward with Low-Carbon Engineering

Nov, 20, 2024 | NewsThe Fehmarnbelt tunnel project is at the forefront of sustainable engineering with its trial of CO2...

Carbon Reduction in Focus: Lessons from the Edge London Bridge Project

Jan, 20, 2025 | NewsA bold new addition to London’s skyline is taking shape near London Bridge. This 27-storey sustaina...

Paving the Future: Sustainable Concrete from Plastic Waste

Jan, 22, 2025 | NewsIn a remarkable innovation, engineers have developed sustainable concrete pavers made from nearly 1...

Concrete's Carbon Capture and Structural Longevity with Supercomputing

Oct, 08, 2025 | NewsResearchers at the University of Southern California have achieved a major milestone in material sc...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

China Completes World’s Longest Expressway Tunnel, Redefining Connectivity

The Line at Neom faces feasibility reassessment while construction continues

The Billion-Dollar Airport Boom: 2025 Megaprojects Shaping the Skies

World's longest expressway tunnel to link northern and southern Xinjiang