Dortmund’s Visionary ICE Plant: Merging Technology and Sustainability in Rail

Sources: railway-news.com, railwaypro.com

Want to read more like this story?

NASA flies over the poles to monitor ice loss

Jun, 22, 2017 | NewsSea ice in the Arctic reached the lowest maximum wintertime extent ever recorded Sea ice in the Arc...

From 5.5 Hours to 3: How High-Speed Rail Will Change Travel in Canada

Mar, 05, 2025 | NewsCanada is set to embark on one of its most ambitious infrastructure projects—the 1,000-kilometre hi...

Arctic Sea Ice Hits Record Low

Feb, 15, 2015 | NewsAccording to data from the NASA-supported National Snow and Ice Data Center (NSIDC) at the Universit...

3D Scanning & AI: The New Era of Rail Infrastructure Maintenance

Feb, 19, 2025 | NewsThe Dutch railway network, with over 7,000 track switches and crossings, faces constant wear and te...

The Largest Ice Shelf In Antarctica Melting

Jul, 06, 2015 | NewsScientists warn that the global warming may cause the detachment of the largest ice shelf in Antarct...

The ‘ice stupas’ could solve the water crisis in the high desert of the Himalayas

Jun, 15, 2018 | NewsArtificial glaciers are used to store the flowing winter water -that otherwise is wasted down the st...

UCI and NASA JPL link Antarctic ice loss to short-term ocean features

Nov, 20, 2025 | NewsResearchers at the University of California, Irvine and NASA’s Jet Propulsion Laboratory report tha...

Hawaii to spend $3.4 billion in infrastructure projects

May, 08, 2019 | NewsThe Hawaiian state will spend a $3.4 billion fund for the construction of new projects and the...

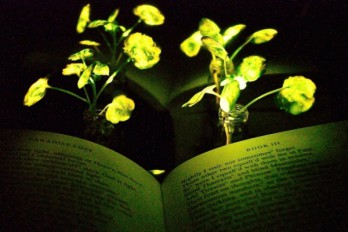

Check out these glowing plants that shine in the dark

Jan, 15, 2018 | NewsThe technology could be used to provide low-intensity indoor lighting, or to transform trees into se...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

China Completes World’s Longest Expressway Tunnel, Redefining Connectivity

The Line at Neom faces feasibility reassessment while construction continues

The Billion-Dollar Airport Boom: 2025 Megaprojects Shaping the Skies

World's longest expressway tunnel to link northern and southern Xinjiang