Eco-friendly bricks grown using bacteria to fight climate change

The process uses zero waste production techniques which also generate no carbon emissions

The process uses zero waste production techniques which also generate no carbon emissions

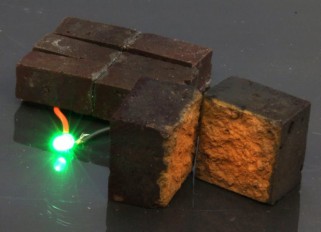

The North-Carolina-based start-up company Biomason has found a revolutionizing way to manufacture bricks. Instead of the traditional clay bricks, whose production requires them heating at high temperatures for 3-5 days to harden -releasing more than 800 million tons of carbon emissions per year into the atmosphere- they came up with a much greener solution. Their bricks are made with sand and aggregate, injected with bacteria and fed with an aqueous solution, sidestepping the use of heat or clay altogether.

The initial idea

In 2005, co-founder of Biomason Ginger Krieg Dosier noticed that there weren’t any green alternative composites for building materials in the market, and wondered if the process by which coral is formed could be replicated in order to make bricks. “I looked at how coral was able to make these incredible structural formations that could withstand water and erosion and began really researching how it was able to grow’’, she says. For this reason, she approached scientists at Research Triangle Park, North Carolina, who concluded that it could indeed be done, but no one had ever tried it before. Since then, her idea attracted commercial investors who saw the market potential, and within 2013 bioMASON quickly raised $2.8 million in seed funding, grants and awards, making her dream come true.

The production process

The bricks are made from sand and aggregate and are packed into rectangular molds. The molds are then inoculated with bacteria, which wrap themselves around the grains of sand, until calcium carbonate crystals begin to form. An irrigation system feeds the brick’s nutrient rich water over the course of several days to facilitate the process. The crystals grow larger and larger, filling gaps between the grains of sand. After 3-5 days, the bricks are ready for use.

The eco-friendly bricks have proved to be as durable as sandstone, and could also be formed in a diverse range of shapes and sizes. The company has already made licensing agreements with two US-based manufacturers of construction materials and is in talks with several more, including two European companies. Biomason’s bricks are expected to be fully-licensed and competitive with standard bricks by 2017, when they will hit the market.

Source: Bio-based world news

Source: Bio-based world news

Want to read more like this story?

Bricks turned into energy storing devices

Aug, 11, 2020 | NewsScientists have found a way to turn classic bricks into electrical storage devices. Red bricks are...

A paving machine makes laying brick roads as easy as it gets

Aug, 23, 2016 | NewsIt can put down more than 300m2 of bricks in a day! It can put down more than 300m2 of bricks in...

Delhi’s Bhalswa landfill waste upcycled into 50,000 eco-friendly bricks

Oct, 03, 2025 | NewsAt Delhi’s Bhalswa landfill, more than 100 tonnes of legacy waste have been upcycled into 50,000 ec...

Building houses out of plastic waste

Sep, 19, 2016 | NewsA portable machine turns used plastic into bricks A portable machine turns used plastic into bric...

Turning bio-solids into bricks

Feb, 05, 2019 | NewsA research team at RMIT University in Melbourne, Australia, has found a method to turn bio-solids in...

3D-printed buildings using soil material

Sep, 24, 2020 | NewsResearchers have developed a new technique to construct a building using a 3-D printer and soil mate...

Portsmouth house collapse: Poor quality of the bricks may cause the partial collapse

Jan, 05, 2023 | NewsA terraced house is believed to have collapsed due to the low grade bricks used to build it. The ho...

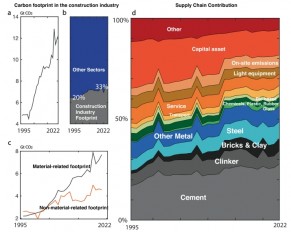

Construction’s carbon footprint to double by 2050, study warns

Nov, 05, 2025 | NewsA new global analysis published in Communications Earth & Environment warns that the constructi...

6-story Bronx building’s partial collapse: façade falls of raining down bricks

Feb, 08, 2022 | NewsPart of the facade of a vacant six-story Bronx building under construction collapsed on Tuesday. Th...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

China Completes World’s Longest Expressway Tunnel, Redefining Connectivity

The Line at Neom faces feasibility reassessment while construction continues