Reliability frameworks for large-scale solar pile foundations

The rapid growth of utility-scale solar installations in the United States has elevated the importance of structural reliability for foundation systems. In 2023, approximately fifteen million steel piles were installed nationwide, representing nearly one percent of all domestic steel consumption. The scale of construction has created renewed interest in how reliably these piles perform throughout their service life.

Although conventional design methods are often applied, the unique characteristics of solar piles raise questions about whether these assumptions consistently achieve appropriate reliability. The absence of long-term datasets, coupled with distinct exposure conditions and installation tolerances, reinforces the need for a structured reliability approach. Modern U.S. reliability practices originate from extensive research in the 1970s and 1980s that led to the development of the Load and Resistance Factor Design framework. This method allows engineers to predict failure probability through calibrated statistical models that combine load characteristics and resistance data.

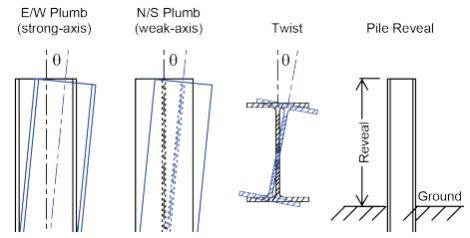

While LRFD provides a unified platform for evaluating structural performance, its calibration largely reflects building and bridge applications. Solar piles differ in several important ways, including their wind-dominant loading, variability in corrosion progression, and greater initial installation imperfections compared to typical building columns. As a result, reliability targets published in ASCE 7 and IBC 2024 provide a starting point but require further validation to fully align with real-world solar conditions.

Solar pile reliability can be qualitatively examined through four categories:

- Safety

- Authority

- Ownership

- Engineering

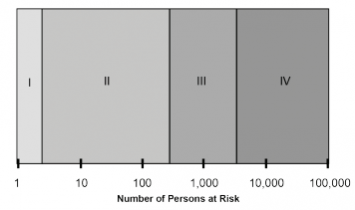

Safety relates to the low life-safety risk associated with ground-mounted solar structures, which historically placed them in Risk Category 1. Authority reflects the role of local jurisdictions, many of which operate several code cycles behind current standards and have limited solar-specific provisions. Ownership involves long-term performance expectations given contractual service lives of twenty-five to thirty-five years that differ from the fifty-year calibration period used in most reliability studies. Engineering encompasses design practice, installation tolerances, corrosion assumptions, and the absence of extensive solar-specific datasets.

Together, these categories highlight where refinements in assumptions, calibration, and long-term monitoring may lead to more consistent reliability outcomes. Continued engagement from stakeholders and ongoing research will be essential for developing clear, consensus-driven expectations across the solar sector.

Sources: structuremag.org/article/how-reliable-are-solar-piles/, structuremag.org

Want to read more like this story?

Drones may help in designing future solar farms

Apr, 18, 2017 | NewsThey can get the job done more quickly and efficiently, while reducing the costs involved They ca...

2016 was a milestone for large-scale solar energy projects in Australia

May, 15, 2017 | NewsWind power has also gained ground in the country as its cost has fallen Wind power has also gaine...

2016 will be a Solar-bright Year!

Mar, 21, 2016 | NewsThe solar sector will most likely add more new electricity-generating capacity than any other The...

Solar Power Expansion Brings Relief to Yemen’s Strained Grid and Offers Hope in the Middle East Energy Scheme

Oct, 01, 2025 | NewsYemen’s first large-scale solar power facility, the Aden Solar Power Plant, is representing a signi...

Things to consider when going solar...

Aug, 04, 2016 | NewsReview these prerequisites before time, to make the installation process run much smoother Review...

Thailand’s first large-scale solar power plant has been operating successfully for 4 years now

Jul, 08, 2016 | NewsIt demonstrates the feasibility of large, private sector solar farms, and leads the way to a greener...

China is the world's biggest producer of solar energy by capacity

Feb, 16, 2017 | NewsThe country’s solar power capacity almost doubled in 2016 The country’s solar power c...

Domestic Solar Panels With The Highest Efficiency In The World

Oct, 07, 2015 | NewsThe American company SolarCity revealed a new solar panel which is described as "the most efficient"...

Solar farms can be really impressive!

Mar, 22, 2016 | NewsTo fully appreciate them, however, you will need a helicopter… Here are some interesting e...

Trending

Taipei 101’s impressive tuned mass damper

Characteristics of Load Bearing Masonry Construction

China Completes World’s Longest Expressway Tunnel, Redefining Connectivity

The Line at Neom faces feasibility reassessment while construction continues

The Billion-Dollar Airport Boom: 2025 Megaprojects Shaping the Skies

World's longest expressway tunnel to link northern and southern Xinjiang