Building Smarter, Greener Structures with DfMA in Mass Timber Construction

Sources: csengineermag.com, vertexcad.com, sltrib.com

Want to read more like this story?

Mass Timber in Affordable Housing

May, 08, 2024 | NewsMass timber is earning its place not only in high-end projects but also in affordable housing, wher...

Washington, D.C.: First mass timber commercial office building opens

Dec, 07, 2022 | NewsThe office building at 80 M Street SE in Washington, D.C., might not stand out if you walked past i...

Carbon Reduction in Focus: Lessons from the Edge London Bridge Project

Jan, 20, 2025 | NewsA bold new addition to London’s skyline is taking shape near London Bridge. This 27-storey sustaina...

Sydney will accommodate the largest hybrid timber tower in the world

Jul, 08, 2020 | NewsThe tallest hybrid timber building in the world is scheduled to be constructed in Sydney, Australia....

Europe’s Largest Timber Development Breaks Ground in Stockholm

Aug, 04, 2025 | NewsAs part of an initiative to align urban development with environmental priorities, Sweden has initi...

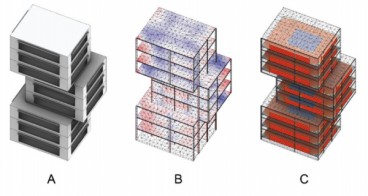

New simulation tool for building design

Jan, 10, 2021 | NewsA new simulation tool that utilizes many variables for the design and the initial phases of the buil...

Hybrid Wood-Steel Systems Deliver Tall Timber Success: The BCIT’s Student Housing Tower

May, 01, 2025 | NewsThe British Columbia Institute of Technology (BCIT) in Burnaby has delivered a milestone in tall ti...

Civil Engineering in the Digital Age: Top Innovations Shaping the Future

Jul, 16, 2024 | NewsThe world of civil engineering is experiencing a significant digital transformation. Innovative tec...

Modern Methods of Construction: Transforming Housing Solutions for a Global Crisis

Dec, 05, 2024 | NewsThe global housing crisis, fueled by rapid urbanization, population growth, and economic disparitie...

Trending

Vertical gardens in Mexico City to combat pollution

Characteristics of Load Bearing Masonry Construction

Taipei 101’s impressive tuned mass damper

Dutch greenhouses have revolutionized modern farming

The Line at Neom faces feasibility reassessment while construction continues

The Line at Neom faces feasibility reassessment while construction continues

King Salman Gate unveiled adjacent to Mecca’s Grand Mosque